Description:

Continuous Optical Signal Transmission Across Rotating Interfaces.

Spin Tact™ Fiber Optic Rotary Joints (FORJs) provide high-speed, EMI-immune optical data transfer across rotating interfaces without signal interruption. They are designed for applications where electrical slip rings alone cannot meet bandwidth or noise requirements.

Key FORJ Capabilities

- Single-channel to 48-channel configurations

- Single-mode (SM) and multi-mode (MM) fiber support

- Wavelengths: 850 nm, 1310 nm, 1550 nm (custom available)

- Low insertion loss (typically <2.5 dB per channel)

- High return loss (>50 dB SM / >35 dB MM)

- Continuous 360° rotation with no optical degradation

- Life exceeding 200 million revolutions

FORJs are commonly integrated into EO/IR gimbals, radar systems, UAV payloads, shipboard masts, and subsea optical links.

Engineering Resources & Next Steps

- Download Technical Datasheets

- Request CAD / STEP Models

- Speak with an Applications Engineer

- Request a Custom Hybrid Configuration

- Technical Specifications

- Documents

- Materials & Contact Technology

- Standards & Qualification

- Applications

Optical Channels | 1–48 (custom available) |

Wavelengths | 850 / 1310 / 1550 nm |

Insertion Loss | <2.5 dB (typical) |

Return Loss | >50 dB (SM), >35 dB (MM) |

Max Rotational Speed | Up to 500 RPM (FORJ) |

Operating Temperature | –40°C to +85°C |

Environmental Sealing | Up to IP68 |

Service Life | 50–300 million rotations |

Connector Options | MIL-DTL-83526, MIL-DTL-38999, LC, SC, ST, FC |

Materials | Stainless steel, anodized aluminum, marine bronze |

Fiber Optic Rotary Joints (FORJ)

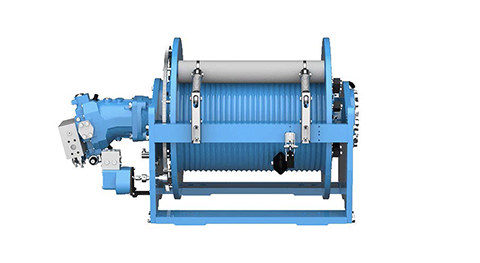

Amphenol Slip Ring & Rotary Joint Solutions for Defense & Industrial Applications

Spin Tact Hybrid Slip Ring

Spin Tact™ products use application-specific contact technologies to optimize performance and longevity:

- Gold-gold contacts for low-noise signal transmission

- Silver/carbon brushes for high-current power transfer

- Ruthenium-plated contacts for low wear and extended life

- Contactless capacitive and antenna-based solutions for ultra-high-speed data paths

These materials are selected to minimize contact resistance, reduce maintenance, and improve MTBF in demanding environments

Spin Tact™ rotary solutions are engineered and qualified to meet stringent industry and military requirements:

- AS9100 manufacturing compliance

- MIL-STD-810G/H (shock, vibration, temperature, salt fog)

- MIL-STD-461G (EMI/EMC)

- MIL-STD-167-1A (shipboard vibration)

- IEC 61753-1 / IEC 61754-20 optical performance standards

Defense & Aerospace

- EO/IR turret systems

- Radar and SATCOM antennas

- UAV and airborne sensor payloads

- Missile seeker and gimbal systems

Maritime & Naval

- Shipboard surveillance masts

- Sonar and towed array systems

- Subsea and underwater vehicles (ROVs/AUVs)

Industrial & Medical

- Robotics and automation

- Semiconductor manufacturing equipment

- MRI and CT imaging systems

- Wind energy and rotating machinery